Language: English

Description

Twist-core is a type of pattern-welding that uses rods of steel that are a laminate of alternating alloys and then twisting them to create patterns. The technique was used to produce knife and sword blades, and later also gun barrels.

It is also commonly known "damascus steel", especially in relation to gun barrels. At the same time, "damascus steel" is also frequently used to describe the crucible steel on some sword blades, as well as other types of pattern welding. As such, I deem the term "damascus steel" too inaccurate to be of good descriptive use.

A Chinese saber with twist-core blade consisting of four rows, indicating that its construction consists of four bars that were twisted, ground down, and welded together.

A Chinese saber with twist-core blade consisting of four rows, indicating that its construction consists of four bars that were twisted, ground down, and welded together.

Geographic spread

Twist-core was used around the world. Some examples: In Europe, it is first seen on Anglo-Saxon swords. Early Ottomans were first famous for their twist-core gun barrels which were soon widely copied in the rest of Europe and parts of the Islamic world, all the way to India. On Ottoman swords and daggers the pattern is referred to as "Turkish ribbon". It is seen on some of the better Chinese blades, where it was called huāwéngāng or "fancy patterned steel". On the Malay archipelago, we see the pattern with some frequency on keris blades of the Moro, Javanese, and Balinese, and sometimes other swords of mainly Indonesia and the Philippines. I have also seen twist-core patterned blades from Tibet, but they are rather rare.

Functionality

Functionally, it can make a stronger piece of steel because the layers are interlocked. This was especially relevant on gun barrels where twist-core could make a stronger barrel with less material, effectively producing a gun of a lighter physical weight that could handle a larger explosive charge. On edged weapons, conventional methods of forging usually made pieces that were strong enough already for their purpose, and twist-core was done more for the added visual effect rather than anything else. Later as our understanding of metallurgy progressed, the same was true for gun barrels.

Technique

Making a twist-core blade or barrel starts with producing a billet with alternating layers of iron or steel of different composition. The bigger the difference between the alloys, the more boldly contrasting the final result will be.

The billet is then cut into bars, each bar being a laminate. Usually at least two bars are used. These bars are then twisted into rods and welded together. Sometimes the sides of the bars are ground down prior to welding together, creating a fairly straight line between the rows of twist in the final result. Other times, they were welded together without grinding, creating a more wavy demarcation between each row of twist.

The billet is then worked into a blade shape. The pattern will distort and stretch when it is hammered out, so in order to create a very fine twist-core patterned blade, it is important to start with a tightly twisted rod and create the billet much closer to the size of the finished blade. The pattern further varies considerably depending on how the bars were twisted, how many bars were used, how deep the bars were ground down, etc.

The extra labor involved is considerable. Especially in olden times, producing the twist-core billet all by hand was a lot of work and welding long rods together required a large oven to heat the long rods in order to connect them. Temperature control was imperative because the rods wouldn't properly weld together if too cold or distort if too hot. For this reason, large pieces with a fine pattern took an exceptional amount of skill in welding. In an age before power tools, the extensive grinding needed to reveal certain patterns was another very laborious task.

Once done, twist-core patterned blades and gun barrels were often etched to reveal the pattern, sometimes deeply so to create a relief.

Twist-core swords are usually among the better swords a culture produced, reserved for the wealthy of their time.

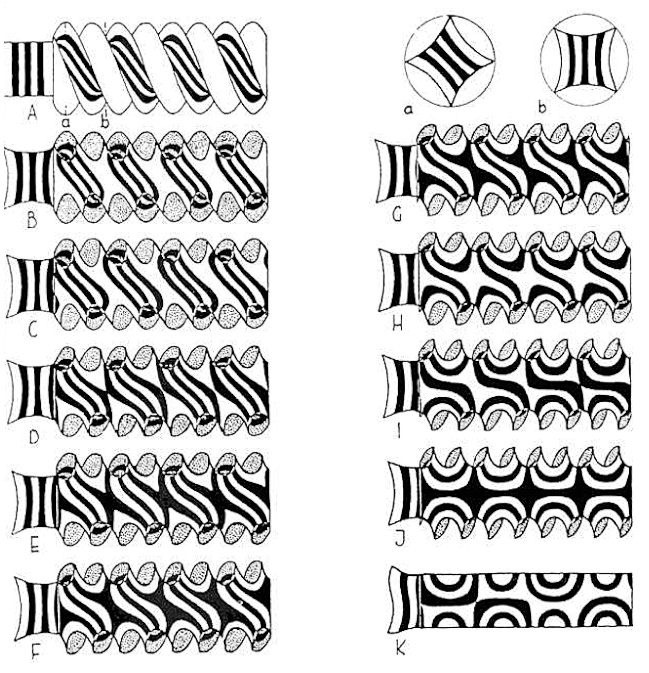

Schematics drawn by Jaap Ypey, a Dutch sword researcher.

A-F shows the variation in pattern caused by increased amount of twist of the bar.

F-J shows how the pattern comes out after grinding more and more.

J is ground to the center of the bar, where the middle layers is now fully exposed.

K shows an alternative pattern if the layers in the initial bar were not flat to begin with.

Twistcore demo piece made by bladesmith Ed Caffrey.

Some antique examples

Here some antique arms I've had over the years with twist-core pattern welded steel.

An Ottoman style bichaq made by Manceaux in Paris, for the Ottoman market.

An Ottoman style bichaq made by Manceaux in Paris, for the Ottoman market.

It is made with a very fine three-row twist-core blade.

An English hunting rifle of the early 19th century with a large caliber Ottoman rifled barrel of the 18th century. The Ottoman barrel with fine twist-core steel, now in English-style browning.

An English hunting rifle of the early 19th century with a large caliber Ottoman rifled barrel of the 18th century. The Ottoman barrel with fine twist-core steel, now in English-style browning.

A tour de force in bladesmithing on a very large 18th-century Chinese presentation saber. It shows a seven-row twist-core pattern on either side of a high-carbon steel plate that is exposed at edge and back. It's not just scaled up, it is also forged many times finer than most. Notice how there is no stretching in the twisted pattern, indicating that this saber was created using a life-sized billet with minimal hammering and maximum grinding. Welding the many rods together on such a long piece was incredibly difficult because temperature control had to be precise throughout.

A tour de force in bladesmithing on a very large 18th-century Chinese presentation saber. It shows a seven-row twist-core pattern on either side of a high-carbon steel plate that is exposed at edge and back. It's not just scaled up, it is also forged many times finer than most. Notice how there is no stretching in the twisted pattern, indicating that this saber was created using a life-sized billet with minimal hammering and maximum grinding. Welding the many rods together on such a long piece was incredibly difficult because temperature control had to be precise throughout.

Also see: